Our work

Structures

3D shapes always involve expensive molds, and for each structure you need a different mould. We challenged ourselves to use this shape in making structural fabrics for furniture.

We rebuilt a machine used in the car industry. This machine glues the fabric to the foam in many shapes. By rebuilding the machine, we made it possible to upscale the size of the sheets, which makes it possible to use them as upholstery fabrics. The fabrics are used in furniture and wall panels.

The fabrics were made in collaboration with KVADRAT and OHMAN and shown for the first time in New York.

A long process of building and testing gave us an insight into producing a larger scale design.

Collaboration with Meubelstoffeerderij.nl , KVADRAT, and OHMAN

BIRCH for Grift

The challenge in this design was making light of a single natural material while also making it look like a cutting-edge design. We love the feel of plywood. Charles and Ray Eames have shown us the possibilities of this material, so we decided to go with this material.

In this design, we lasercut the shades out of the sheets of plywood into shapes, preventing waste as much as possible. Using the material properties that give the design its strength: the material is flat and flexible but strong when curved. Held together with a stick of ash wood, the total shade becomes a single material piece. The shade is simply hung over the led module with steel wires.

Besides natural, it’s also possible to choose one of the amazing colours of INTO paint by UULA. INTO is an environmentally friendly linseed oil and plastic-free paint.

Working with the possibilities of plywood was a great journey. The lamp is made in different sizes, which makes it possible to make many different sets.

Collaboration with UULA

Designed for GRIFT

TIMBER. For VEPA Made for VEPA

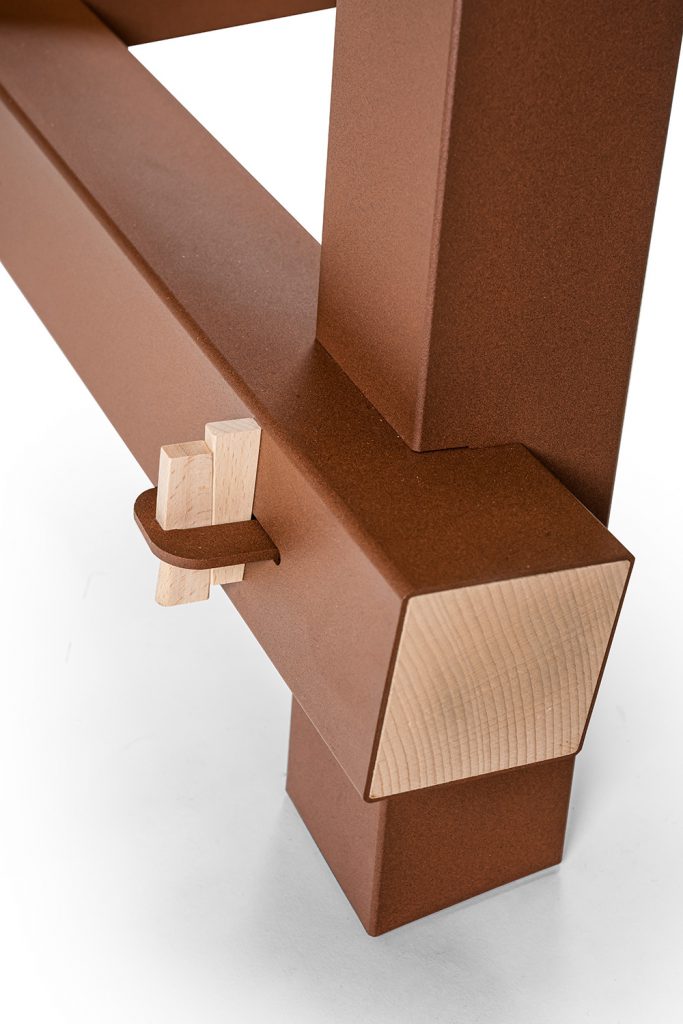

Making a table with no glue, screws, or welding was a challenge. We found the solution in an old technique still used in the building of farmhouses: pinhole construction.

With precision laser cutting technology in-house at VEPA, it was possible to make this connection out of steel. The result is TIMBER. The world’s first table, constructed without the use of glue, screws, or welding.

It was a great experience to collaborate with the engineers of VEPA. The process was interesting: working with talented people, solving problems along the way, and towards a great result.

This technique of assembly we used creates a sustainable product. Parts of the table can be replaced when damaged. We made sure that all parts could be separated and recycled into raw materials for a new life cycle. Therefore, it is possible to send the table as a flat-pack product, which saves a lot of shipping space.

Collaboration with VEPA.nl

Designed for VEPA

TUBE for Label

The challenge in this project was making a chair with a single material frame. Usually, the frame of a chair consists of many different parts and different materials. We came up with a design for a chair with a frame covered with a leather seat. Following the installation of the seat, the legs are clamped to the frame.

Steel coil springs are directly mounted into the frame. The upholstery is a cover made of leather but can also be made of canvas fabric. The filling of the cushions is made of wool. This way, the seat can be easily removed from the frame, and the steel of the frame can be repainted or recycled.

This technique is not only visually appealing, but it also creates a sustainable product: parts of the chair can be replaced when damaged. And all parts can be separated and recycled into raw materials for a new life cycle. Also, it is possible to send new seat covers as a flat product, which saves a lot of shipping space.

The collaboration with Meubelstoffeerderij has been great: we both share a great passion for chairs, especially the construction of them.

Collaboration with Meubelstoffeerderij.nl

Created for a label design competition

SOFT LIGHT for Grift

We have always been big fans of Kvadrat’s Hallingdal fabric: a 1965 designed woollen fabric, made in beautiful colours.

The advantage of a “soft” light would be that the light could be folded flat when sent to the customer. The wool shade is easy to clean and replace when damaged. The flexible cone is simply connected to the round raster.

The result is a very soft, iconic, but strong shape. The light raster is 3D printed with sustainable PLA

The PLA is made of soja and corn. The raster functions as a light diffuser.

It has been a great experience for our studio to work with a 3D printer and the Hallingdal fabric. Fabrics have always been a favourite material to work with. Figuring out the connection between the raster and the fabric shade was a great challenge, but thanks to our studio’s many tries,

It finally worked out great.

Collaboration with KVADRAT fabrics

Designed for GRIFT

Insert.

With this design, we used the flexibility of a stiff material for the comfort of a chair. The material of choice is aluminium, a material which is very light and not very strong when not used in the right way.

We wanted to create the shape of the frame with the function of holding parts of the chair. The result is a minimalistic shaped chair with a maximum of comfort. The frame holds the backrest, which gives the backrest a bit of movement. This adds a lot to the comfort of seating, as it bends a bit when sitting down.

Our studio has always been fascinated by the construction techniques of Pierre Paulin for Artifort’s design. A fascination and inspiration for the inside of a chair.

Collaboration with Meubelstoffeerderij.nl